ORGANIC RANKINE CYCLE

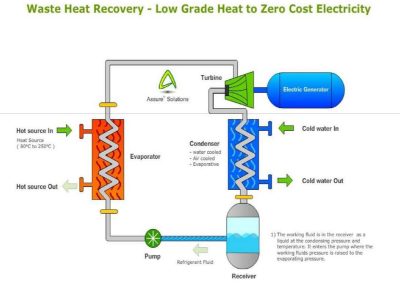

The Organic Rankine Cycle (ORC) is named for its use of an organic, high molecular mass fluid with a liquid-vapor phase change, or boiling point, occurring at a lower temperature than the water-steam phase change. The fluid allows Rankine cycle heat recovery from lower temperature sources such as biomass combustion, industrial waste heat, geothermal heat, solar ponds etc. The low-temperature heat is converted into useful work, that can itself be converted into electricity.

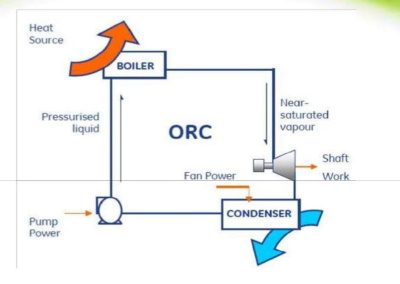

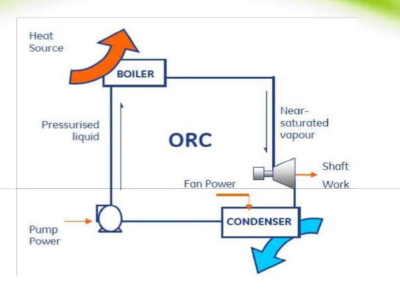

Working principle of the ORC

The working principle of the organic Rankine cycle is the same as that of the Rankine cycle: the working fluid is pumped to a boiler where it is evaporated, passed through an expansion device (turbine, screw, scroll,or other expander ), and then through a condenser heat exchanger where it is finally re-condensed.

In the ideal cycle described by the engine’s theoretical model, the expansion is isentropic and the evaporation and condensation processes are isobaric.

comparision between conventional steam v/s organic working fluid

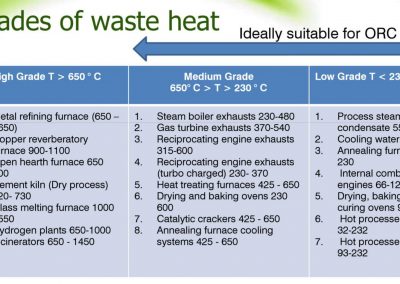

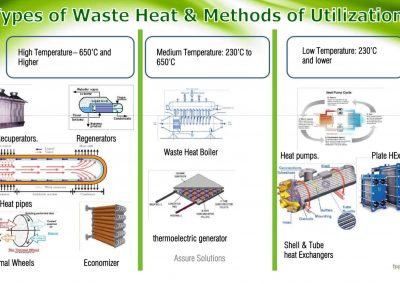

For many ( Low Temprature ) waste heat applications, we need a fluid that boil at lower temprature than water.

- Historically such Fluids have been Hydrocarbons hence the name is Organic.

- Modern Working Fluids include Propane | Pentane | Tolune | HFCR245fa

- These Working Fluids allow use of Lower temperature Heat Sources because the Liquid vapour phase change, or boiling point occurs at a lower temprature than the water steam phase change.

STEAM CYCLE

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

ORC POWER GEN

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

EXPANDER TURBINE

- Compact , Reliable ORC Expander Design

- Variable Speed , High Efficiency Generator.

- Fluid- Cooled Integral Power & Control Electronics.

- Oil-Free magnetic bearings for high speed & efficiency.

- Modular design for wide power ranges.